Resazurin Reduction Test (RRT)

Resazurin reduction t is another method of dye reduction test and the principle of this test is nearly similar to methylene blue reduction test. In MBRT the time for reduction of the dye is measured, while in RRT, at a fixed period time, specific shade of colour and its intensity is measured. There are two variations in RRT of testing milk. One is 10 min RRT test that can be used as a rapid platform test for quick assessment of milk at the raw milk reception dock. The other one is a one hour RRT performed in the lab. In this we will talk about Rapid RRT.

Principle

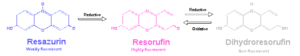

- Unlike methylene blue the resazurin undergoes reduction through a series of colour shades viz., blue, purple, and lavender, pink before completely getting reduced to colourless.

- Resazurin dye which is blue in colour at the oxidation-reduction potential of + 0.3 volts undergoes an irreversible change to pink colour compound (resorufin) when the redox potential reduces to +0.2 volts.

- When the redox potential is reduced further to + 0.1 volts or less, the colour of dye changes to colourless (dihydroresorufin), which is a reversible reaction. Usually, the degree of reduction of the dye is measured after a fixed time of incubation of milk sample in the presence of dye.

- The reduction of dye to a particular shade of colour is dependent upon the extent of depletion of oxygen by metabolic activity of microbes. The colour change is measured with the help of a Lovibond colour comparator and a standard resazurin disc.

Standard solution of resazurin

- One tablet of Resazurin is dissolved in 50 ml of cold sterile glass distilled water by gentle heating to facilitate the dissolving. This is the bench solution for direct use and should always be used as fresh.

- Alternatively dissolve 0.05 g of resazurin powder in 100 ml of distilled water and boil the contents for 30 min. This will make a standard solution of 0.05%, which should always be kept in a cool and dark place, stored in an amber coloured bottle.

- The bench solution (0.005%) for regular use should be prepared freshly by diluting the standard solution with distilled water i.e. 1 ml of standard solution with 10 ml of distilled water.

Procedure

- Take 10 ml of milk into a test tube and add 1 ml of working solution of Resazurin solution.

- Put air tight closure to prevent oxygen entry

- Invert the test tubes to mix the milk and Resazurin solution.

- Place the test tubes in a thermostatically maintained water bath at 37 ±5 °C and note down the time of incubation (10 min).

- At the end of incubation match the colour of the milk with one of the colour standards of Resazurin disc.

Resazurin chemical structures

Grading of milk

The quality of raw milk is adjusted by using the following parameters.

Advantages of dye reduction test

- Used for estimating the suitability of milk for liquid consumption.

- These tests are cheaper and less time is required.

- With the help of these tests the activity is measured rather than the number of bacteria.

- Unlike the artificial media used in SPC, in milk the natural environment for microbes is present.

- In case of RRT, the results can be measured in a shorter time.

- Some of the bacteria capable of reducing the dye may not develop colonies on the medium used in SPC.

Disadvantages

- Rate of reduction of dye varies considerably and is related to species and the rate at which different micro-organisms grow at a particular temperature.

- Inhibitory substances like penicillin and other antibiotics prevent the growth of bacteria and thus increase the reduction time.

- Not suitable for classifying milk with low bacterial counts of less than 105 /ml.

- Reduction capability may vary because of variation in proportion of bacteria carried into cream layer by the rising fat globule.

- These tests do not give indication for the type of micro-organisms present.

- Temperature of incubation used during these tests is not the optimum for majority of the micro-organisms present in milk.

- Not suitable for testing quality of pasteurized milk intended for processing because of the low number of micro-organisms.

- Require continuous attention until reduction takes place.